Filament Tolerances

Is tolerance important?Filament tolerance is really ... really important - don't let anybody tell you otherwise.

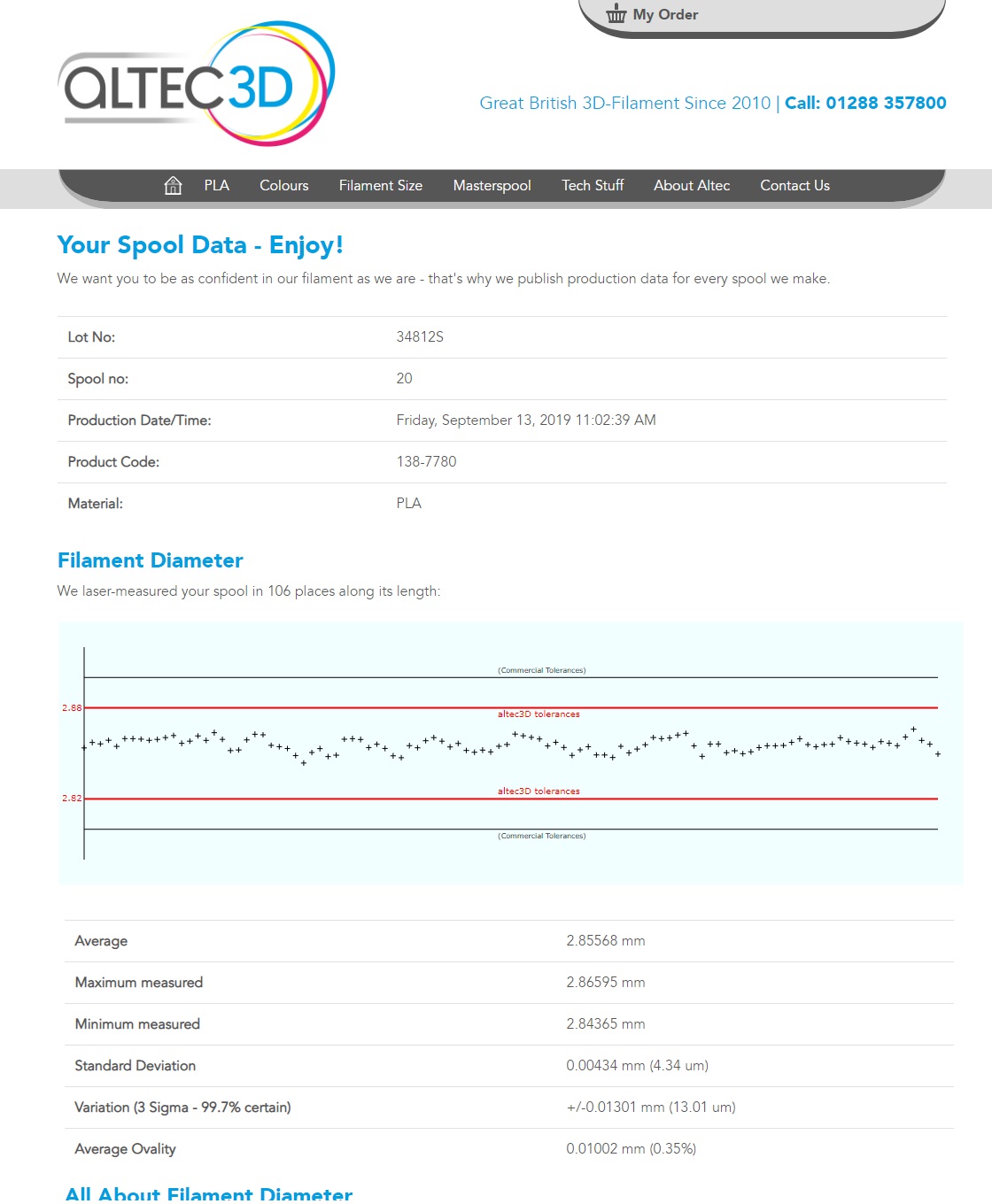

We think it is so important we publish the size data for every spool we make. (See screenshot).

What's the tolerance?

Everything that's engineered has a tolerance, and filament is no different. Unlike injection moulding, filament extrusion is continuous (think - sausage maker!). This means it is suseptable to changes in the many parameters that need to be controlled to ensure good filament. And just like any engineers you get good extrusion companies (like us) and … well, not so good.

'Commercial' tolerances

Commercial tolerances of +/-0.05mm are just not good enough for excellent 3D Prints. This tolerance could mean your printer is under- or over-extruding by up to 6%. Anyone quoting +/-0.05mm are probably not measuring properly anyway (ask for their data) and are probably not even achieivng +/-0.05mm - don't even go there!

The main effect of poor tolerance filament is bad layers, poor layer adhesion or under- or over- extrusion.

Our tolerances

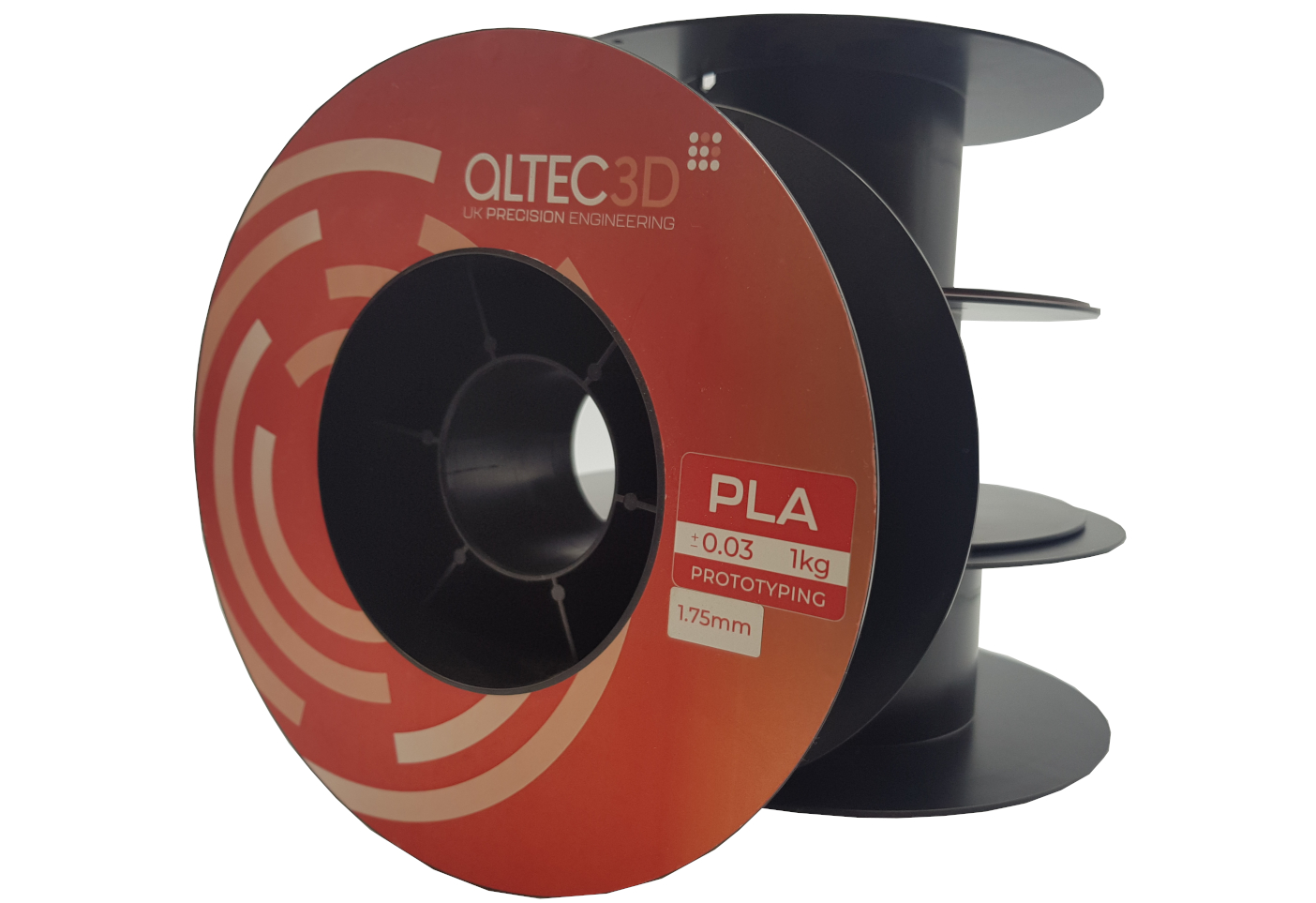

Our tolerances are +/-0.03mm, which means your hot-end will be extruding within 3% of what you are expecting - perfect print layers - perfect prints.

Statistical Techniques

The tolerance is not the end of it though. Even though we're measuring every few centimetres, we want to make sure ALL your filament is in tolerance, not just the bits we measure. We do this by applying a statistical technique called Standard Deviation. Standard Deviation works out the variation for the bits we haven't measured directly - really clever stuff! All this means you'll never get a bulge, bump or thin spot.